Table of Contents

ToggleClient Instructions

The client reported that their Foster EP 700 HL commercial freezer was overheating. The issue had escalated to a medium/urgent priority as they had been attempting to book an engineer for the past two weeks but had been let down by other companies.

Engineer’s Work

Upon arrival, the engineer immediately attached gauges to the system and found that the freezer had no refrigerant. The following steps were taken:

- Removal of Components: The evaporator cover, fans, and evaporator tray were removed for further investigation.

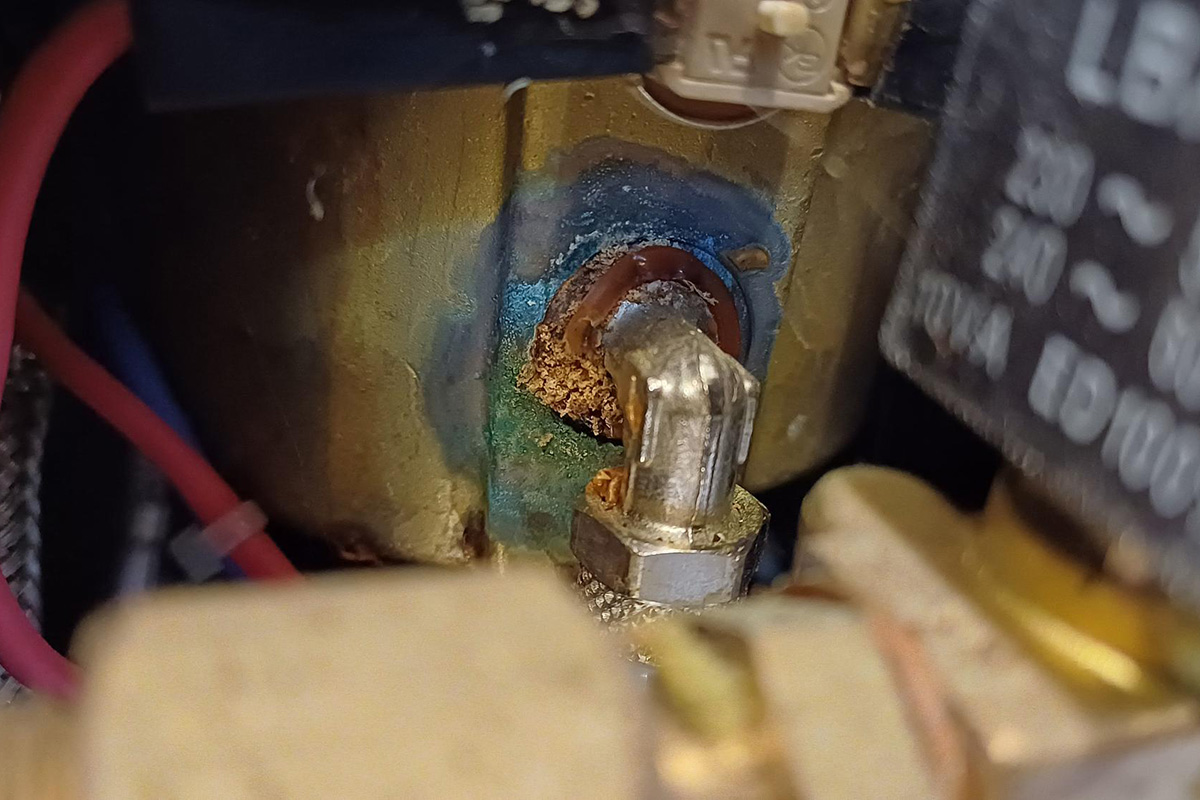

- Leak Detection: Using an electronic leak detector, a leak was identified in the evaporator coil. The detector activated around the coil, confirming the source of the issue.

- System Recharge: The system was charged with R404A refrigerant from van stock, and all panels, fans, and covers were reassembled.

- Temperature Monitoring: The freezer’s temperature was checked during the process. The initial temperature was recorded at +4°C. After recharging the system and completing the repairs, the temperature dropped to -18°C, indicating that the freezer was now fully operational.

- Additional Checks: The engineer carried out a thorough check of the controller parameters, including:

- Set point and differential values.

- Defrost parameters, including duration, end temperature, and intervals.

- A check on the condenser fan and coil revealed that the coil was slightly blocked, which was subsequently cleared.

While the freezer is now ready to use, a new evaporator coil will be required to permanently resolve the issue.

Unit Details

- Make: Foster

- Model: EP700HL

- Serial Number: E533567

Spares Required

- 1 x Evaporator Coil (to be ordered from the supplier)

- 500g R404A Refrigerant (from van stock)

- Bottles of OFN (from van stock)

- MAP Gas & Brazing Rod (from van stock)

Parts Used

- R404A Refrigerant

Foster EP 700 HL freezer repaired and back to -18°C

The Foster EP 700 HL freezer, which had been experiencing overheating due to a lack of refrigerant and a leak in the evaporator coil, was successfully repaired. The freezer is now functioning correctly, maintaining a temperature of -18°C. However, for a long-term solution, the evaporator coil will need to be replaced.

The client expressed satisfaction with the efficiency of the work, especially after having been let down by other service providers.

We continue to offer reliable, professional commercial refrigeration repair services across London and the surrounding areas, ensuring minimal downtime for businesses that rely on efficient cooling systems.

For more information about our services or to book a visit, contact us today!

With many years on the tools in all aspects of the engineering industry has given me a second to none skill set which enables me to provide a leading professional service to my customers with a wealth of knowledge and highly skilled engineers to successfully cover all your plumbing, heating, AC and catering equipment requirements.